We're here to help:

Easy ways to get the answers you need.

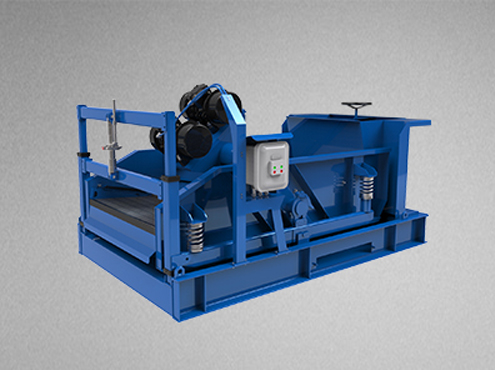

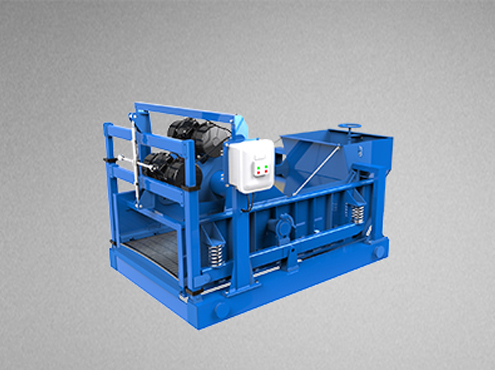

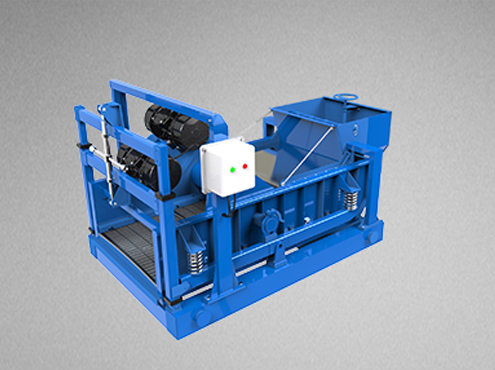

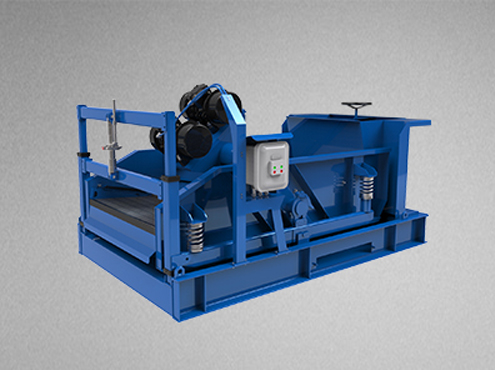

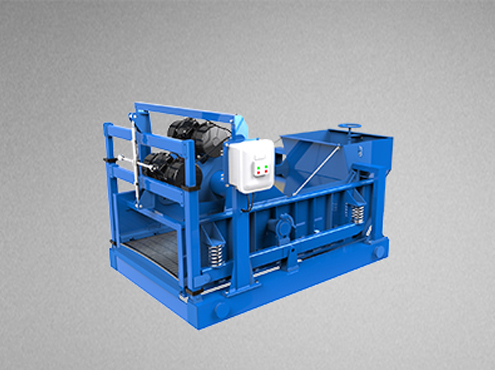

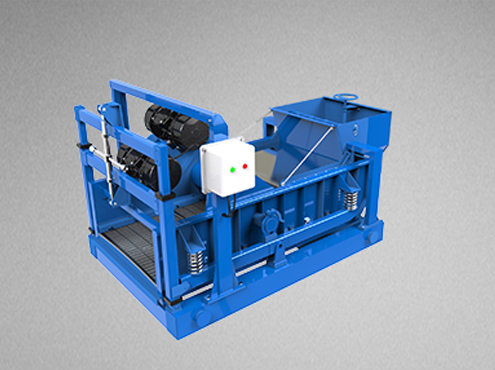

The KOSUN drilling fluids shale shaker is the first stage of solids control equipment in drilling mud system. Shale shaker can remove cuttings above 75 μm brought from the drilling well to leave the liquid with smaller particles into the tanks below, which will flow into next grade solids control equipment for further treatment.

1. G-forces linear motion up to 7.4 G(adjustable depending on the situation)

2. Hi-speed conveyance of cuttings

3. Higher shaker-fluids capability

4. Able to process heavier solids loads

5. Enhance cuttings processing volume

6. AWD device is adjustable from -1°~5°

7. Single side shaker screens tension system to change the shaker screens easily

8. Shale shaker feeder can be weir feeder or box feeder

9. Hook-strip shaker screens

As the solids control equipment manufacturer, KOSUN has own patented linear motion shale shaker, which features durable welded structure. In details, KOSUN shale shaker features vibration motor & screen plate base, which can be installed into screen basket with special parts. Screen basket is fixed on the adjustment beam. At each of the four vertexes of the shale shaker screen, basket can put a vibration damping spring, which can usually prevent the adjoining parts and devices from being affected by the vibration. There are several shale shaker screen panels on a screen basket. They are fixed and adjusted by snap-on screw bolts and hooking tensioners so that the combined effect of horizontal and vertical supporting bars can provide enough strength for screens basket. The panels are in an arched shape, which can make panels more easily tensioned and intimately connected with the frames, extending their service life as well as increasing the processing efficiency of particles.

KOSUN patented AWD angle adjustment system can raise or lower the end of screen basket while the machine works. This part includes two vertical column assemblies that are connected on the upper beam assembly and are attached to the shaker base. The mobile part of AWD consists of the lower beam, limiting device that controls vertical movement and screw rod that drives the upward and downward movement of the screen basket. Both ends of screw rod are hinged with the upper and lower beam assemblies respectively. Positive and negative rotating handles can make the screen basket move upward and downward respectively. The screen basket angle of oilfield shale shaker can be arbitrarily adjusted within -1°~5° at an increment of 0.5°when being required.

The mud returned from the well or cuttings to be treated will flow into the drilling mud shale shaker via the feeder. The feeders can be categorized into weir type, box type and bucket type. The weir type and box type feeders are mainly used to buffer the flow rate of drilling fluid and evenly distribute the fluid onto the screen so as to reduce the impact of drilling fluid on the shale shaker screen, extend the service life of screen and improve the treatment effect. Besides, the weir type feeder can also short-circuit the machine if necessary. The bucket type feeder is mainly used with the dryer shaker to collect and distribute cuttings.

KOSUN linear motion shale shaker is especially effective while drilling top-hole sections where heavy and high-volume solids are usually encountered. In these intervals, shakers may generate powerful G-forces and its effective vibrating motion can quickly remove the dense solids from shale shaker screen and particles from wells.

Since 1992, with more than 20 years of industrial experience of manufacturing and design, KOSUN has won its reputation across the worldwide clients. It is the largest and professional drilling solids control equipment manufacturer in China. It can provide and design full range of solids control equipment for different operation capacities and requirements. The main products of KOSUN include oilfield shale shaker, decanter centrifuge, desander, desilter, mud cleaner, vacuum degasser, centrifugal pump, submersible slurry pump, shear pump, mud agitator, mud gun, jet mud mixer, mud tank, diesel tank, water tank, complete solids control system, etc.

Any question or support, please fill in the form below,we will get back to you as soon as possible!!